Automatic dose filling, sealing and packaging machine - Seal Pack Technology

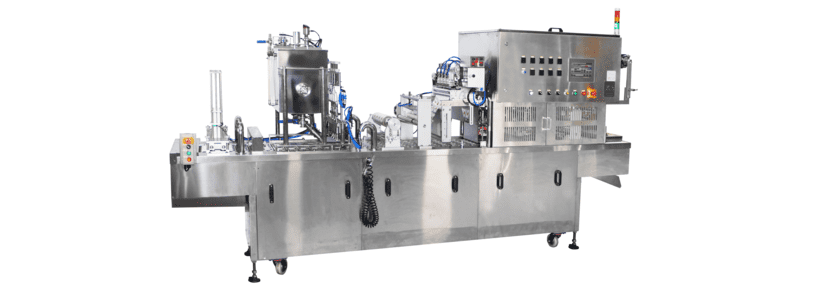

Seal Pack Technology Co., Ltd. is a well-known designer and manufacturer of automatic dose filling, sealing and packaging machines. For 30 years (1993-2023), Seal Pack has a good reputation in providing packaging machines that meet customer requirements. Regardless of the physical properties of your product, whether it is liquid, powder or solid (granule), Seal Pack can meet your requirements for packaging your product in cup, tray, jar, bottle and stand-up pouch. Seal Pack is not only have clients in Taiwan, but also all continents around the world (Asia, Africa, Europe, America and Australia), with a total of sales to 60 countries.

Seal Pack has the courage to use new electric control components. In November 2014, Seal Pack applied servo driver for dose volumetric pston filler. So that users can set the filling volume via HMI, allowing the machine to adjust the filling volume automatically and can significantly reduce customer adjusts time costs. We also gradually introduce electronic control components from world-renowned brands (SIEMENS / AB / OMRON / MITSUBISHI...etc.) to provide customers with different choices of operating control systems.

Feature:

- Entire machine is made of stainless steel 304 and anodized aluminum alloy to comply with food hygiene and safety regulations.

- Auto Feeder of cup/tray/jar/bottle/can/stand-up pouch.

- Auto Dose filler, Liquid: Gravity, Volumetric Piston, Rotary Lobe Pump, Screw Pump, Flow Meter.

- Auto Dose filler, Powder: Measuring Cup or Volumetric Cup & Auger.

- Auto Dose filler, Granule: Measuring Cup or Volumetric Cup & Weighing Scale。

- Product contact part is made of stainless steel 304 as standard and customer can also purchase stainless steel 316 for their need.

- Sealer: Roll film (laminated with plastic material) or Pre-cut foil.

- Auto Lid Applicator.

- Auto Cartoner.

- Mold Fast Interchange design.

- HMI touch screen operation can set and modify the internal parameters of the machine and can automatically display error messages to facilitate troubleshooting and maintenance.

- Remote Connect to the Internet remotely to check the operation status of the machine.

Product:

- Liquid: Drinking water, Sauce, Juice, Yogurt, Bean curd, Chicken soup, Herbal jelly, Aiyu, Tofu, Soybean, Konjac & Nata de Coco strip syrup, Laundry detergent, Conditioner, etc.

- Powder: Soda powder, Energy drink powder, Coffee, Milk tea, etc.

- Granule/Solid:Biscuits, Candy, Tea, Cereal, desiccant, Ice cube, Popping boba, Instant noodles, Meal tray, etc.

|

Machine model |

2202B |

1204B |

|

Video |

||

|

Website page |

||

|

Power supply |

Depend on the installation location and power source |

Depend on the installation location and power source |

|

Machine size |

L 1500 * W 1500 * H 2000mm |

L 4000 * W 1000 * H 2000mm |

|

Capacity |

1800-2400 cups/hr |

3600-4800 cups/hr |

|

Entire machine material |

Stainless steel 304 and anodized aluminum alloy |

Stainless steel 304 and anodized aluminum alloy |

|

Operation control |

HMI touch screen, Proface, Chinese/English language interchange |

|

|

7” |

10” |

|

|

Rapid change mold formula |

10 sets |

|

|

Temperature controller |

Omron |

|

|

PLC control |

Mitsubishi |

|

|

Ethernet hub |

Phoenix or WAGO or SOLOMON |

|

|

Inverter |

DELTA |

|

|

Solid state relay(SSR) |

FOTEK |

|

|

Circuit breaker |

Shihlin / SCHNEIDER |

|

|

Magnetic contactor(AC) |

Shihlin / SCHNEIDER |

|

|

Circuit protector |

Shihlin / SCHNEIDER |

|

|

Relay |

Omron |

|

|

Proximate switch |

Pepperl+Fuchs-Germany |

|

|

Air cylinder |

Festo(Main)& Chanto(Sub) |

|

|

Air hose |

Festo |

|